SurfaceGLAZE

SurfaceGLAZE Process Steps

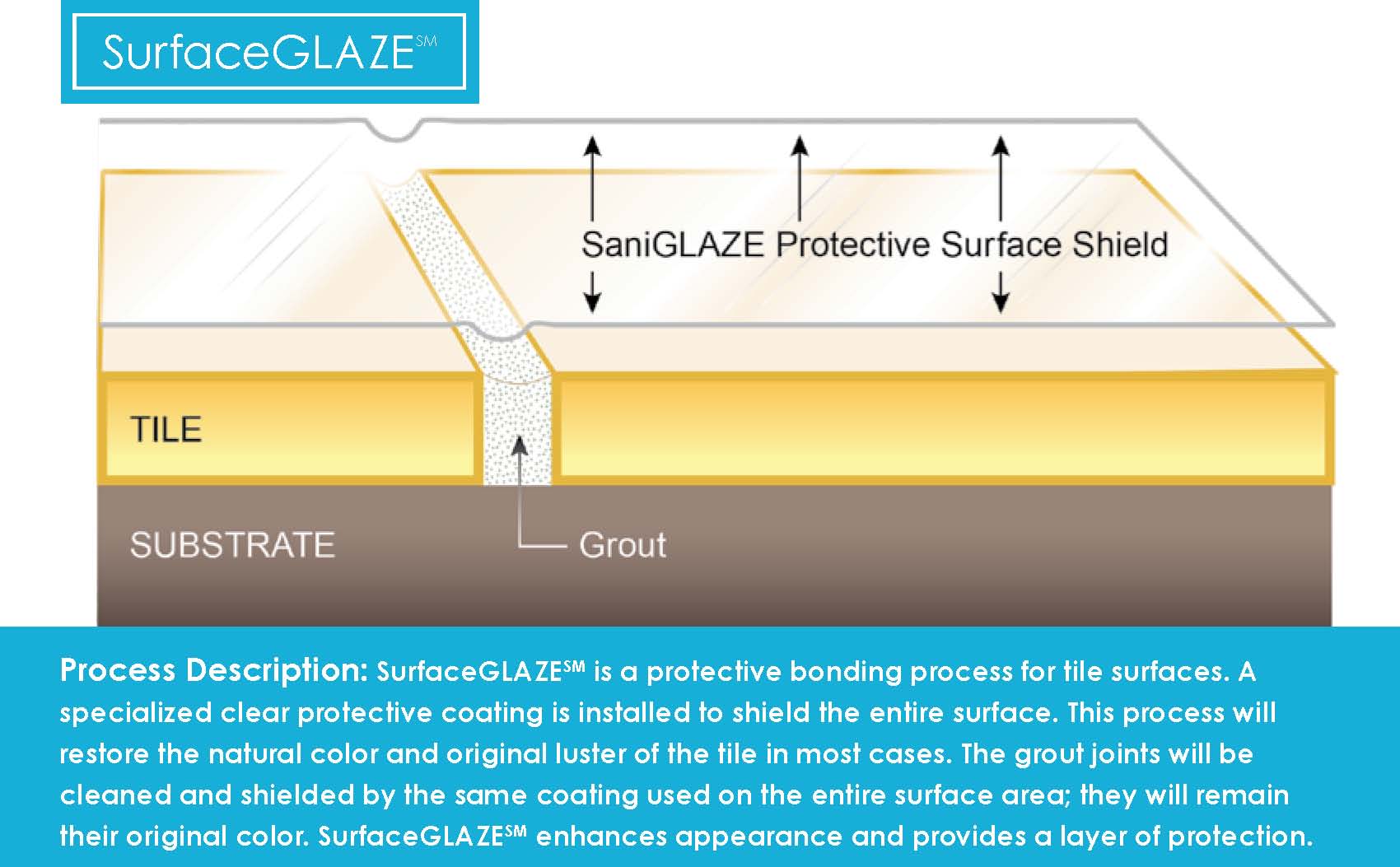

Step 1: clean and prep entire surface using SaniGLAZE’s xcelKLEEn process to remove contaminants and to prepare tile and grout for application of SaniGLAZE® coatings.

Step 2: Install appropriate SaniGLAZE® protective shield for the entire surface.

Primary Products Used

The coatings specified for the SurfaceGLAZE process depend on several factors. your SaniGLAZE® service professional can advise you on which coating is best.

Surface Shield Group:

- Super Shield®: durable, clear topical polymer coating suitable for a wide variety of tile types.

- SaniTECH®: Urethane based coating formulated for heavy use and high maintenance areas.

- SaniMAX®: formulated from xolite, a revolutionary polymer that is ultra-durable and very easy to clean.

- SaniSEAL®: An exceptional penetrating sealer (impregnator) used for quarry, brick paver and Saltillo tile; and situations where a topical coating is not recommended.

Benefits:

• Improves the appearance of the tile surface

• Protects against soil and moisture penetration

• Eradicates foul odors

• Repels bacteria, mildew, and mold

• Simplifies maintenance

• Improves the appearance of the tile surface

• Protects against soil and moisture penetration

• Eradicates foul odors

• Repels bacteria, mildew, and mold

• Simplifies maintenance

Where and When to Specify:

SurfaceGLAZE is specified for large or small tile sizes. It is recommended for areas that do not require extensive restoration. And where the grout joints are in good condition and do not require a color change or restorative treatment other than cleaning.